It is common knowledge that the foundation of any building needs to be strong enough to bear its load. In addition to vertical loads, buildings are also subject to horizontal loads during earthquakes, heavy winds and hydrostatic pressure. In order to avoid any damage or calamity to the buildings, it is only wise to design foundations considering these diverse conditions. Sometimes the loose nature of the soil or excessive water table is an impediment to constructing an economic shallow foundation. It is at these times, we need to go in for pile foundation or piling in building construction.

Piling in building construction

In pile foundation, it is common to drive piles upto a depth where rock or hard soil is available so as to transfer the building load to it. Piling therefore ensures a sturdier base for your building to safeguard its stability.

What is piling in house construction and why is it necessary?

Essentially, piling in house construction is a process where long structural members (typically steel or concrete with reinforcement steel) are driven deep into the soil. This ensures an even distribution of the building loads over a large surface area. For multi-storeyed residential buildings in areas with loose soil like dried-up waterbodies, seashore, river-banks, etc, piling is essential. In addition, for large commercial buildings, considering the heavy loads, engineers recommend piling or pile foundation even where the soil strength is not very weak.

If you use shallow foundations in the afore-mentioned cases, it will not transfer the building load to the soil evenly. This tends to cause subsidence in the soil and will lead to instability of the building. In most of such cases, the huge load of the building will result in fracture of the foundation and superstructure. This could well result in the collapse of the building.

Advantages of piling in building construction

Primary to providing a solid and strong foundation, the use of piling in building construction has many advantages.

- First of all, Piles can be pre-made in any length or size, which can reduce construction time.

- Driving piles results in compacting and densifying the soil around it, thereby increasing the soil bearing capacity.

- The work is neat and clean and requires less supervision than regular shallow foundations.

- Moreover, the use of piling in building construction ensures that the building can take more load than in regular foundations.

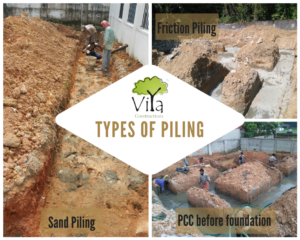

Types of piling in house construction

End bearing piles – where the bottom end of the pile rests on rock or strong soil. The pile, which acts as a column transfers the building load to the bottom.

Friction Piles – where the load is transferred across the full length of the concrete pile to the surrounding soil.

DMC piles– Direct Mud Circulation is in common use in areas where space is a constraint. It consists of the distribution of mud from the pile bore directly to a bentonite pit. A pump recycles the bentonite slurry and abandons the settled mud. Bentonite is pumped into the bore during drilling so as to stabilise the sides of the bore hole. As drilling proceeds, bentonite is washed out at the top. Concreting is done when density of the bentonite+water mix is less than that of concrete. This causes the concrete to settle down.

Rotary piles – a more recent type involving the use of tungsten/diamond cutting tools for boring. Used where noise/vibration free boring is a must. However, this type is very expensive. It is mostly used for industrial applications and where time is a factor.

Sand piles – This method involves filling of a pre-driven steel pipe with sand. The pipe is withdrawn while the air pressure is directed against the sand inside it. A bottom plate opens during withdrawal ensuring sand flows into the voids created earlier during the driving of the pipe. The sand backfill prevents the soil surrounding the pipe from collapsing as it is withdrawn. During this process, the soil gets densified.

What are Piles in building construction made of?

Current construction practices mostly go in for concrete piles (round or hexagonal). These can be cast in situ. Another option is to go in for steel beams, which can take very high loads and save construction time. However, the disadvantage here is less resistance to moisture.

In areas with more water content or corrosive soil, concrete piles would be preferable. Wooden piles have been known to be used in early times. The limitation here being the length of a single tree, as joints cannot be made. The beautiful city of Venice is a classic example – it boasts of age-old buildings built on wooden piles.

You may also like: Stages of building construction

Step by step approach for piling in house construction

Now that we have seen what piling is, and why it is necessary before building construction. Let us look at a step by step approach on how to carry out piling in house construction.

1: Do you need to do piling for your house construction?

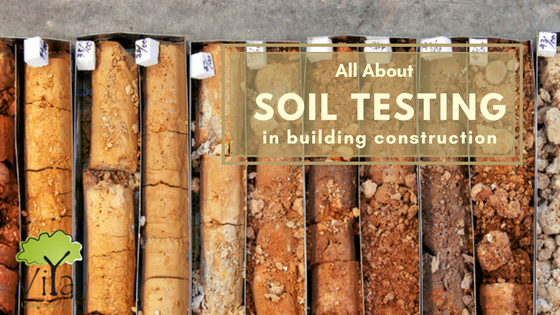

So, how is one to decide whether to opt for pile foundation for your building? Your structural engineer is the best person to decide. The construction contractor would carry out a soil test, which would determine the soil bearing capacity. Soil chemistry, corrosiveness, water content, salinity and a host of other characteristics also serve as key parameters. The soil test report, alongwith the proposed weight of the building serves as inputs to the structural engineer to perform the structure design. He would also suggest a foundation recommendation, taking into consideration all the above-mentioned inputs.

If the structural engineer recommends a normal rubble foundation, you need not worry about piling.

2: My soil test report reveals that the soil is not strong enough and my structural engineer has recommended pile foundation. What should I do next?

Alright, this means that you should have a detailed discussion with your structural engineer to determine the level of reinforcement required. As an outcome of the discussion, you would know the number of piles to be used and it’s depth. Obviously this would mean shelling out some initial cash on piling, but you would rather not live in your new home with a fear of collapsing, would you?

3: How is piling in house construction done?

Now that you have decided to do the piling, you should engage a good piling contractor. They use different machinery to drill holes in the soil and fill it with concrete. The type of piles to be used, number of holes and depth of each hole would depend on the recommendation of the structural engineer. After the piling process, the ground is filled with soil again.

4: How do you build the foundation on soil that has undergone piling?

As mentioned above, after piling, the ground is filled with soil again. At this stage, the ground would look exactly like what it was before piling.

The next step is to identify the piles, expose the steel and chip the piles. This process is known as pile chipping. Pile chipping is done to connect all the piles using the foundation. This enables further construction on top of the reinforced ground.

5: What are the types of connections in pile foundation?

The simplest type of connection is the pile beam. Here a simple concrete bar is used to connect the various piles.

Another method is the usage of pile caps. In this method, dome shaped caps are used to connect the piles.

Pilot bores would give a fair idea as to what depth stronger soil or rock is available. With all these inputs and knowing the applicable loads, he would then design an ideal pile foundation for your building.

Remember, there are no cutting corners when it comes to piling in building construction. For, your entire building depends squarely on its reliability!

JOHN V.S.

i have 20 cent plot. i wish to construct a 4 storied residential quarters. but the land was digged for building constructions stones before 20 years. some areas digged upto 10 years. now it is filled with soil 10 years before. may i can build a quarters.

Foundation for your House Construction in Kochi - Viya Constructions

[…] Piling […]