The Strongman Cement

Not a day goes without our seeing advertisements in the media adulating ‘strong’ cements. Walls built with “best cement for house construction” which elephants cannot break, battering rams cannot even scratch or explosives cannot bring down! As a discerning user, shouldn’t you be aware of the basics of cements? Here we are with some facts, which will undoubtedly help you in choosing the best cement for house construction.

What is Cement?

Cement is basically a mixture of limestone (gypsum) and clay. It is manufactured by burning this mixture in a rotary kiln and grinding to a fine powder. Cement has adhesive and cohesive properties. These properties help in bonding solid matter into a compact mass. The resultant mass has very high strength and is very durable. Furthermore, it also has very good resistance to corrosion. It is also capable of withstanding vagaries of the weather for very long years.

Types of Cement for house construction

There are about 19 types of cement available commercially. Each type has its uses and advantages, based on its constituents. However, for our understanding, a general classification would be Hydraulic and Non- hydraulic cement. Hydraulic cements are those which harden in the presence of water by hydration. Non hydraulic cements do not need water to harden. Instead they utilise the Carbon-dioxide in air for the same. As a result, non-hydraulic cement harden when kept dry.

Commonly used cement for house construction

The most commonly used types of cement for house construction are Ordinary Portland Cement (OPC) and Portland Pozzolana Cement (PPC). No doubt, you would have observed these nomenclatures on cement bags.

OPC cement is the most common and widely available form of cement. OPC is the basic ingredient of concrete. It is manufactured by processing limestone and clay minerals to form clinkers. The clinkers are then powdered in a cement mill and gypsum is added. It is the gypsum that provides the desired setting qualities to the Portland Cement.

The PPC is a variant of the OPC. When you add Pozzolana, a kind of volcanic flyash to OPC, you get PPC. PPC usually consists of approximately 65-70% OPC clinkers, 5% gypsum and 25-30% Pozzolana. The resultant Portland Pozzolana Cement is stronger and more durable than the OPC. Since PPC employs natural and industrial waste, it is reduces the environmental load. For the same reason, PPC is a green building material.

Portland Cement is usually considered the best cement for house construction across the world.

A comparative study – OPC and PPC

Ordinary Portland Cement (OPC) |

Portland Pozzolana Cement (PPC) |

|

| Constituents | 95% cement clinkers, 5% gypsum | 65 -70 % cement clinkers, 5% gypsum, 25-30% Pozzolana |

| Setting time | Initial setting time is 30 minutes. Final setting time is 280 minutes. | Initial setting time is 30 minutes. Final setting time is 600 minutes. |

| Strength | Initial strength is higher and is therefore recommended when you need high strength in the initial stages. | Addition of Pozzolana makes this stronger and more durable than OPC in the long run. |

| Curing time | Minimum 7 days | Minimum 10 days |

| Durability | Durable | Highly durable even in adverse conditions. |

| ISI mark | Black coloured mark | Red coloured mark |

| Grades | Grade 33, 43, 53 | Single grade that matches with OPC grade 33 in strength |

| Applications | Manufacture of Concrete. Construction of buildings where strength is the major criteria. For eg. Commercial and industrial complexes, High-rise Building, Roads, Bridges, Flyovers etc. | Brick masonry, plastering, tiling and waterproofing works where strength is not the major criteria |

| Cost per bag | Slightly more expensive (approx Rs 5/- per bag) than PPC. |

To summarize

- OPC has greater resistance to shrinkage. Hence, they are less prone to cracking in the long run.

- Setting time is faster in OPC and therefore it is more productive to use OPC.

- Curing time is less in OPC and is therefore it is more cost efficient.

- However, durability of OPC is less than that of PPC, as they are less fine and have higher permeability.

- With less cohesive strength, OPC concrete is more difficult to pump.

- OPC is slightly more expensive than PPC.

OPC therefore qualifies as the best cement for house construction.

Grades of Ordinary Portland Cement

Cement grades are specified by its compression strength in Newtons/sq mm achieved after 28 days of setting. Commonly used in India are Grades 33, 43 and 53. The numerals indicate its strength. The Civil Design Engineer determines the usage of a specific grade of cement, depending on the application.

Other types of cement used in construction

In addition to the commonly used cements discussed above, there are many other types of cement also. However they are manufactured for specific requirements. Mostly, they find major use in industrial applications. Some of them are :

- Rapid hardening cement – decreases the setting time and hence forming costs.

- Quick setting cement – used for concreting for water bound structures.

- Sulphate Resisting Cement – used where soil contains sulphates which are harmful to civil structures.

- High Alumina cement – used in marine construction, sewer infrastructure and high temperature applications like furnaces and boilers.

- White cement – used for decorative/ornamental purposes, external renderings, terrazzo surfaces, swimming pools etc.

- Hydrographic cement – used to repel water in structures like dams, causeways, canals etc to ensure longer life.

- Blast furnace slag cement – used where strength is not a consideration with a view to reduce cost.

- Expansive cement – used for grouting machinery anchor bolts as it does not shrink during setting.

Of course, the constituents and manufacturing processes of each of these types of cement are different from one another.

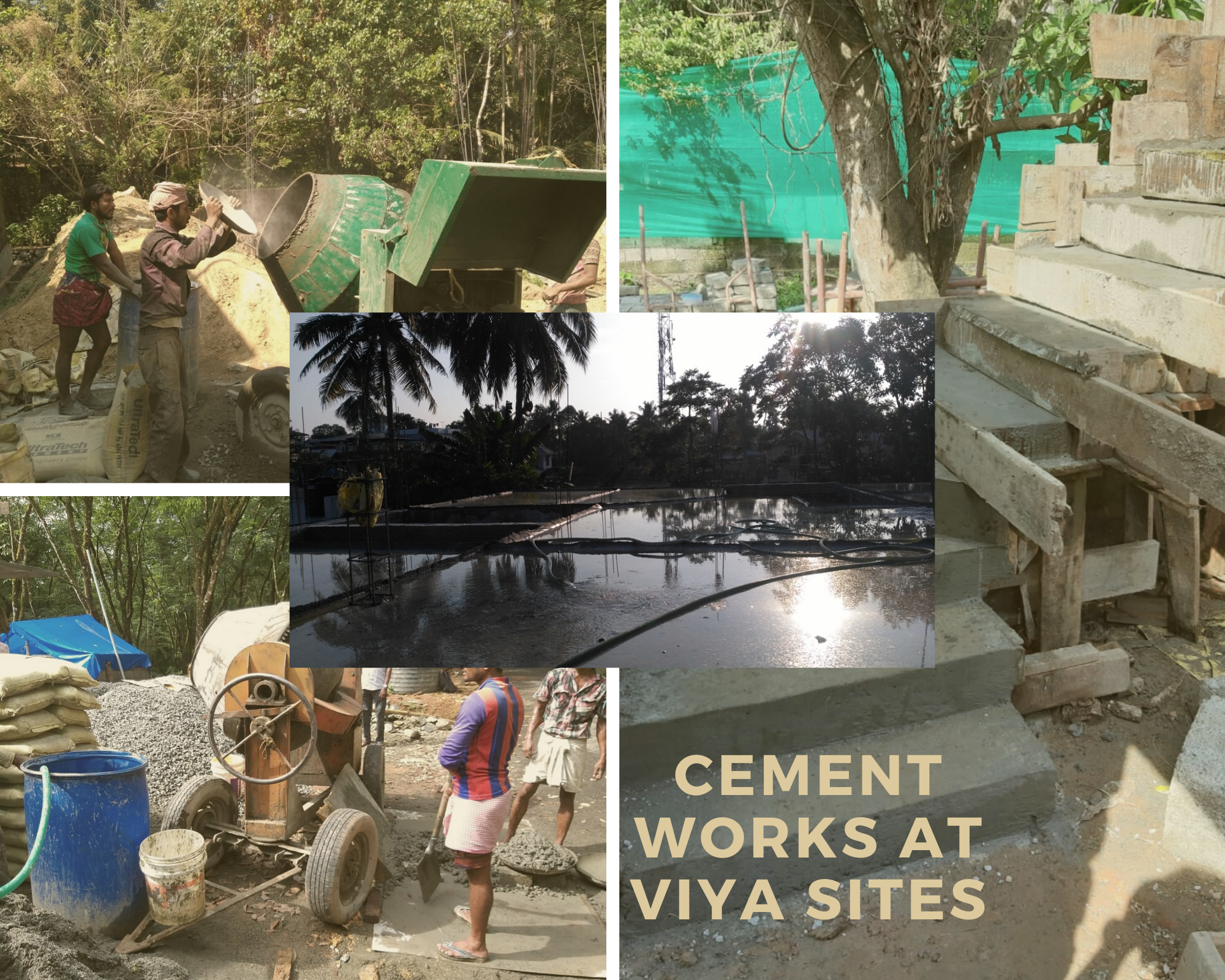

Cement works at our various sites

Concrete Mixes

Concrete used for construction is basically a mixture of sand, gravel or crushed stone, water and cement. These are mixed thoroughly in pre-determined quantities, based on the strength required. This requirement is fixed by the Civil Design Engineer, depending on the nature of the structure to be cast. In certain cases steel will be used to reinforce the strength of concrete and it is called Reinforced Cement Concrete (RCC).

Indian Standards designate the concrete mixes by the compressive strength in Newtons/sq mm after 28 days of casting. The most commonly used grades of cement are M10, M15, M20, M25, M30, M35,M40. Numerals indicate the respective strength of the mixes using given ratios of cement, sand and water. In special areas of construction, higher strength mixes like M50, M60, M70 etc are also used.

Tips for long lasting concrete

Obviously, everyone of us would desire that our house lasts a lifetime, without any defects or problems. For this, it is essential to ensure that we use only the best quality concrete. Some tips which will help achieve this are :

- Ensure that you use only top quality raw materials, primarily cement and steel from well known sources.

- Make sure that you use only the best cement for house construction, don’t fall into the trap of choosing cheaper alternatives.

- When procuring raw materials, insist on test certificates for proven quality.

- Make sure of proper storage and minimum exposure to the elements before construction.

- Test the soil to ensure that sulphates are not present. If present, the Design Engineer will recommend usage of proper Sulphate Resistant Cement.

- Test the water being used to ensure that there are no detrimental salts or sulphates present. Check for allowable total dissolved solids (TDS) and water quality. This will eliminate corrosion and crack failure in the long run.

- Ensure that cement, water, are aggregate mixes are in the recommended proportions.

Never reduce the curing time for concrete, as this will considerably reduce its strength.

Usage of cement in house construction

In house construction, the area of application determines the type of cement. Listed below are some of the common areas of application and the best cement for house construction:

| Application | Cement Type |

| All RCC structures | OPC Grade 53 or 43 |

| Masonry, Plastering and Tiling | PPC |

| Decorative areas and frontages | White cement |

| Foundation for poor soil | SRC |

Watch this video on how to choose the best cement for house construction

Let this be the beginning of our strong bond!

We are sure the above information has been useful and informative. For any specific queries on house construction, please feel free to get in touch with us.

Finally, the next time you see an advertisement showing an elephant unable to break down a wall, remember that there are many things which go into making a ‘Strong’ cement wall! best cement for house construction

best cement for house construction

Why to add a layer of PCC before foundation? Viya Constructions

[…] concrete is a product obtained artificially by hardening the mixture of cement, sand, gravel, and water in predetermined proportions. When these ingredients are mixed, they form […]