Steel for construction purposes comes as long bars about 12 m in length. This has to be cut and shaped into desired forms as required by the structure that you are building. Details on the length and shape of how the steel bars have to be cut are usually given as part of the structural design by the structural engineer. The process by which the steel bars used for construction are cut into smaller pieces suitable for construction is called Bar Bending.

Bar Bending is an important aspect of building construction and happens in every construction site.

Bar Bending Schedule (BBS)

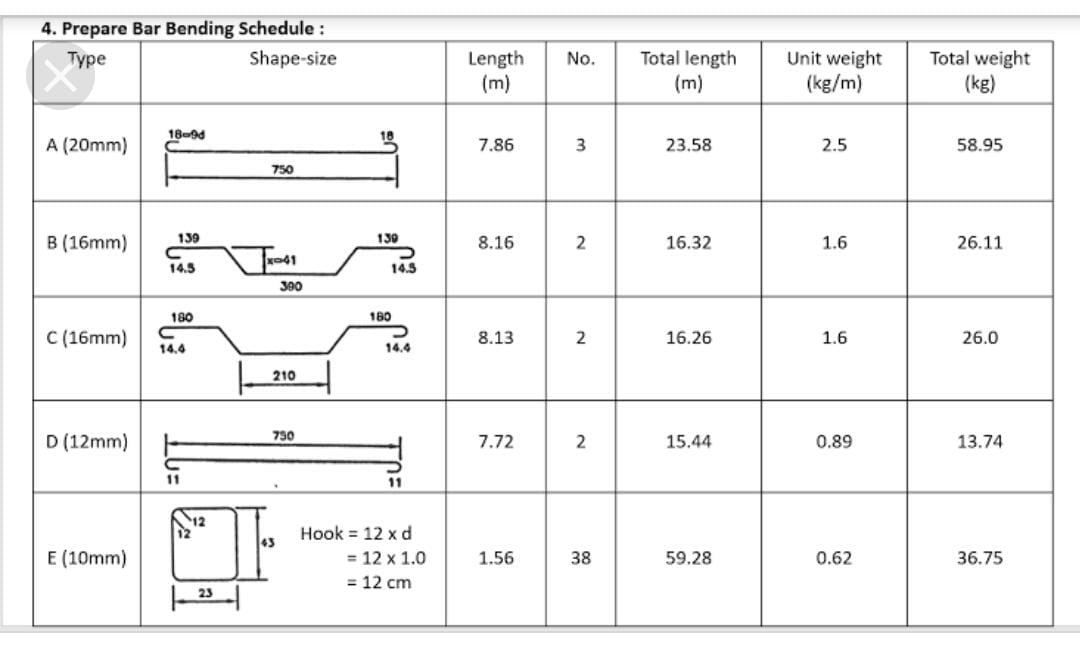

For the bar bending to the done accurately and in tandem with the structural drawings, a Bar Bending Schedule (BBS) is issued. The BBS is a comprehensive list that contains details like the length in which the steel bar has to be cut, where to make the bends, how many bends to be made, number of bars of each type etc. The BBS is created in accordance with the SP 34: (1987) code

Sample Bar bending Schedule: Source Internet

The Bar Bending Schedule helps the manual labourers at site have a fair idea about the work they need to do. It also helps them do the job right the first time, reducing the wastage of expensive building materials.

Bar Bending Tools

There are several tools used for the process of bar bending. A chopsaw, Bar bender, and Bar bending key are a few of them.

A bar bending key is made from steel alloy. It has a hooked end that is hardened enough for maximum power to bend the steel bar.

You might also like: How to choose the best cement for construction

How is bar bending done at a worksite?

In this video we look at how bar bending is done in one of our worksites.

The steel bars for construction purposes come as a long bar of length 12m. The first step of Bar bending is to straighten out these steel bars. This is to be done manually. This bar has to be cut into desired lengths by using a Chopsaw. The length and number of steel bars depend on the structural requirement for each site.

The cut pieces are then bent using a bar bender key. A hollow pipe that is strong enough to bend the bars can also be used.

Bar bending can also be done by using a bar bending machine.