Fact :

Most prospective house owners pay scarce attention to the quality of the raw materials used in their construction.

The truth:

Sadly, it is true that while most people take pains to select quality plumbing /electrical fittings and sanitary ware, they thoroughly disregard selection of raw materials!

The most often cited reason is lack of technical knowledge! Therefore, in the interest of quality and thereby, longevity of your house, we opine that everyone should understand the basic tenets of construction.

Quality of raw materials like cement, brick and steel go a long way to enhance the durability of your abode. In this article, we take you through basic information on steel in construction, from a layperson’s point of view, simple and straight.

Steel in construction - Why and Where?

Basically, steel is used to enhance strength in RCC structure. Reinforced Cement Concrete, as you are aware; is a proportional mix of cement, sand, water, gravel and additives with steel. Steel bonds easily with cement concrete. This results in a homogeneous structure upon setting. Moreover, steel is also ductile (malleable). Steel also has a thermal expansion coefficient equal to concrete. Specifically, this latter property of steel ensures better bonding, thereby reducing chances of failures when exposed to different ambient temperatures.

Concrete by itself is strong in compression but weak in tension. This is the main reason for using steel in concrete. Furthermore, it allows concrete to withstand tensile forces that would otherwise crack apart unreinforced concrete.

Steel is mostly used in foundations, roof slabs, columns and beams. Lintels, sunshades and staircases too need steel reinforcement. Window frames, Grill work, gazebos and hand rails also use steel, though recent trends prefer aluminium and other light weight materials.

Steel in construction – why and where?

Types of steel in construction

Commonly used steel for construction are TMT and HYSD. They are both named on the basis of their process of manufacture. Thermo Mechanically Treated bars have high strength and are also ductile. High Yielding Strength Deformed steel are heat rolled and cold twisted.

TMT bars are normally considered better for construction. This is because they have higher tensile strength, less surface flaws, more ductility and corrosion resistance. TMT is also found to be more effective in earthquake zones. Importantly, it would need approximately 8 to 11% less TMT steel than HYSD for like constructions. TMT steel is less reactive to concrete, thereby ensuring less rust formation, which is a major reason for cracks in RCC in the long run.

Yet another commonly used type is TOR steel, which is essentially a type of HYSD steel. These undergo cold twisting and deformations on the surface to facilitate better bonding with the concrete.

Overall, considering the strength, corrosion resistance and most relevantly, the economics, the industry prefers to use TMT steel in construction.

Types of steel in construction

Grades of TMT Steel in construction

TMT steel for construction purposes is available commercially in two grades viz, Fe415 and Fe500. The numbers indicate the yield stress of the steel in Newton/sq mm. Though Fe500 has a higher strength, ductility of Fe415 is better. Fe415 is therefore commonly used in general construction. These are available in sizes ranging from 6 mm to 32 mm diameter. The design requirement determines the type of steel. This in turn is calculated based on the loads acting on the particular structural member or area.

Grades of TMT Steel in construction

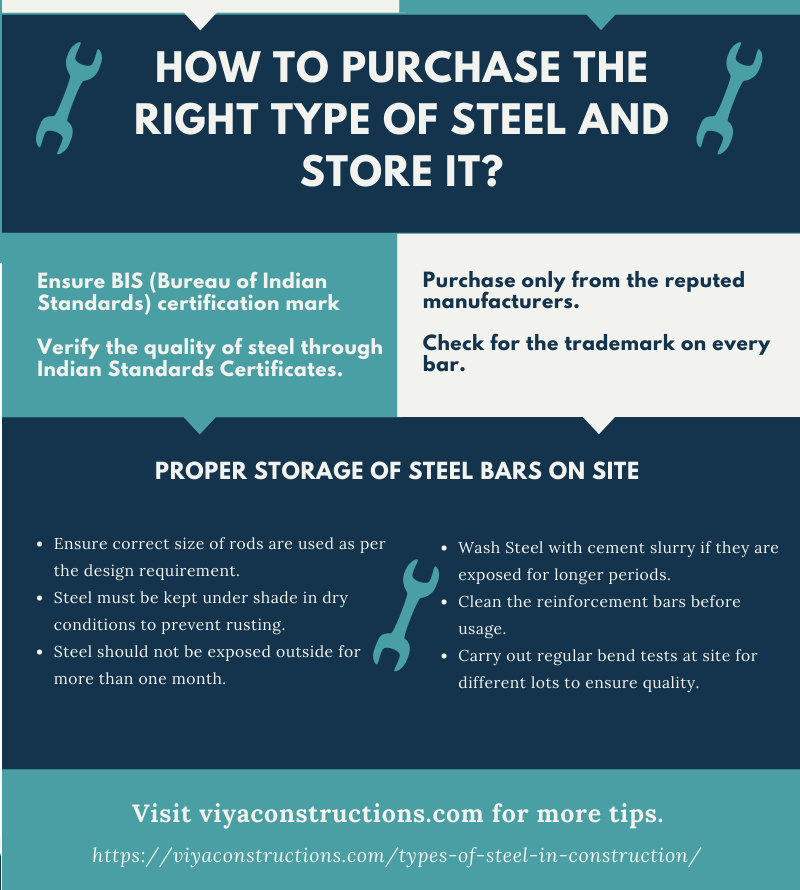

Purchasing the Right Steel

First of all, whilst procuring steel for your project, make sure to take up the following with your contractor.

- BIS (Bureau of Indian Standards) certification mark.

- Verify the quality of steel through Indian Standards certificates.

- Purchase only from the reputed manufacturers.

- Check for the trademark on every bar.

However, purchasing good steel is not the end of it all. Besides this, you should ensure due attention to good practices for storage and usage at site.

- Proper storage of steel bars on site is a sheer necessity.

- Ensure correct size of rods are used as per the design requirement.

- Always keep Steel under shade in dry conditions to prevent rusting.

- Do not expose Steel outside for more than one month.

- Wash Steel with cement slurry if they are exposed for longer periods.

- Clean the reinforcement bars before usage.

- Carry out regular bend tests at site for different lots to ensure quality.

Facilitate the Superman in your house

Types of steel

Therefore, it ensues that little care and effort you take ensures long term benefits in your house construction. In short, take proper care of the steel you use in your house construction and it will take care of your house for a life time! Facilitate the superman in your house!

10 Basic Civil Construction Materials - Viya Constructions

[…] commonly used types of steel in construction are the Thermo Mechanically Treated (TMT) bars and the High Yielding Strength Deformed (HYSD) […]

How to do Bar Bending in construction - Viya Constructions

[…] purposes come as a long bar of length 12m. The first step of Bar bending is to straighten out these steel bars. This is to be done manually. This bar has to be cut into desired lengths by using a Chopsaw. The […]

How to choose the best cement for house construction | Viya Constructions

[…] by the Civil Design Engineer, depending on the nature of the structure to be cast. In certain cases steel will be used to reinforce the strength of concrete and it is called Reinforced Cement Concrete […]

Steel Structures in Civil Construction - Viya Constructions

[…] Additional Reading: Types of steel in construction […]